XJTU research team’s breakthrough in harnessing duplex titanium alloys

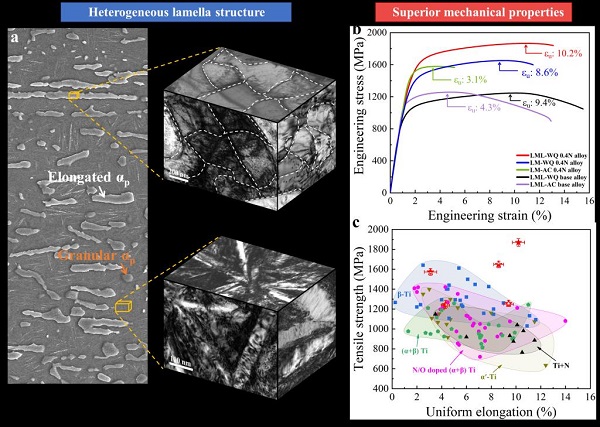

The heterogeneous lamellar structure of Ti-Cr-Zr-Al-0.4N (wt.%) alloy.

Duplex titanium alloys (α+β), one of the most important high-specific-strength structural materials, can achieve a wide range of mechanical properties by tailoring the HCP-α phase. However, high-strength duplex titanium alloys often suffer from a low work hardening rate (WHR, Θ), resulting in limited uniform elongation (εu).

To address this issue, a team led by Academician Jun Sun and Professor Jinyu Zhang from the State Key Laboratory for Mechanical Behavior of Materials at Xi'an Jiaotong University (XJTU) has demonstrated that the typically adverse effect of interstitial nitrogen (N) atom-dislocation interactions can be reversed to enhance the strength and ductility of duplex titanium alloys.

Using a simple cyclic hot rolling and short-time solution treatment process, the team controlled N-dislocation interactions at high temperatures to tailor the microstructure of a Ti-2.8Cr-4.5Zr-5.2Al-0.4N (wt.%) duplex alloy.

For the primary α (αp) phase, N-dislocation interactions not only facilitated wavy slip and generated sufficient dislocations during hot rolling but also impeded dislocation annihilation during short-time solution treatment. This facilitated the formation of low-angle grain boundaries (LAGBs) enriched with N atoms.

For the high-temperature β phase, this interaction transformed the planar stress field of edge dislocations into a non-planar configuration, leading to the formation of interstitial N-strengthened coherent α-nano-twinned martensite (α-NTNMs) upon quenching.

Consequently, a heterogeneous lamellar structure was constructed, comprising lamellar αp grains bounded by N-enriched LAGBs, and a β-transformed microstructure consisting of interstitial N-strengthened α-NTNMs.

This heterogeneous lamellar structure elevated the alloy's flow stress to a level sufficient to activate the critical resolved shear stress (CRSS) for <c+a> dislocations. This caused the N-enriched LAGBs and coherent α-NTNM interfaces to act as prolific dislocation sources, promoting c-axis deformation and wavy slip. Simultaneously, these N-enriched LAGBs and coherent α-NTNM interfaces allowed dislocations to transmit across them, alleviating stress concentration.

This lamellar structure, ingeniously designed by harnessing N-dislocation interactions, endowed the interstitial N-doped Ti-Cr-Zr-Al duplex titanium alloy with exceptional room-temperature mechanical properties: ultra-high yield/tensile strength of ~1532/1869 MPa and a large uniform elongation (εu) of ~10.2 percent, coupled with a high work hardening capacity (σUTS - σy) of ~337 MPa.

These properties surpass all currently reported titanium alloys. The team's proposed dual functionality of interstitial atom-dislocation interactions for constructing unique microstructures enables the achievement of ultra-high strength and large tensile ductility in interstitial-strengthened titanium alloys, with promising potential for extension to other high-performance alloy systems.

This research has been published online in Advanced Science under the title Harnessing Bifunctional Nitrogen-Dislocation Interactions for A Record Ultra-strong-and-ductile Duplex Titanium Alloy.