XJTU research team achieves breakthrough in metallic glass research

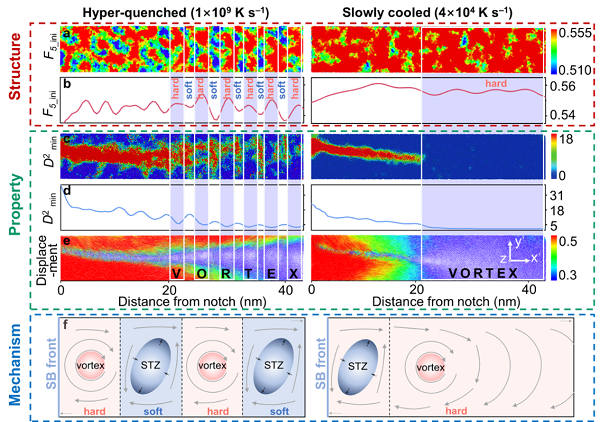

Atomic-scale mechanism of shear-band front propagation to the center of the sample.

Metallic glasses (also known as amorphous alloys) exhibit exceptional mechanical properties such as high strength and elasticity due to their disordered atomic structure. However, this same structure makes them prone to forming nanoscale-localized shear bands during plastic deformation.

The initiation and propagation of these shear bands often lead to brittle fracture, significantly limiting the engineering applications of metallic glasses. Understanding the microscopic mechanisms behind shear band formation and propagation has become a challenge in condensed matter physics, materials mechanics, and computational materials science.

To address this, a research team led by Professors Ding Jun and Ma En from the Center for Alloy Innovation and Design at Xi'an Jiaotong University's (XJTU) State Key Laboratory for Mechanical Behavior of Materials employed their previously developed molecular dynamics-Monte Carlo (MD-MC) hybrid simulation method.

They investigated the structural evolution and shear band behavior in Mg₆₅Cu₂₅Y₁₀ metallic glass under cooling rates spanning nine orders of magnitude – from 10⁴ K/s (comparable to experimental casting conditions) to 10¹³ K/s (typical for MD simulations).

This study is the first to reveal the atomic-level mechanism by which structural state governs shear band propagation in metallic glasses. The findings provide new insights into the microdynamics of shear band initiation and growth, highlighting how tuning the structural state can control shear band behavior. This opens up new avenues for optimizing the mechanical properties of metallic glasses for specific engineering applications.

The research, titled Structural state governs the mechanism of shear-band propagation in metallic glasses, was recently published in the Proceedings of the National Academy of Sciences.