XJTU publishes research result of new-type hydrogen-tolerant Al alloys in Nature

Submicron dispersoid particles formed during homogenization or solution treatment exhibit hydrogen-trapping properties and distribution characteristics intermediate between constituent and precipitate particles.

In response to the critical demand for hydrogen-tolerant Al alloys, the research team led by Professor Liu Gang and Academician Sun Jun from the State Key Laboratory for Mechanical Behavior of Materials at Xi'an Jiaotong University (XJTU) conducted systematic research.

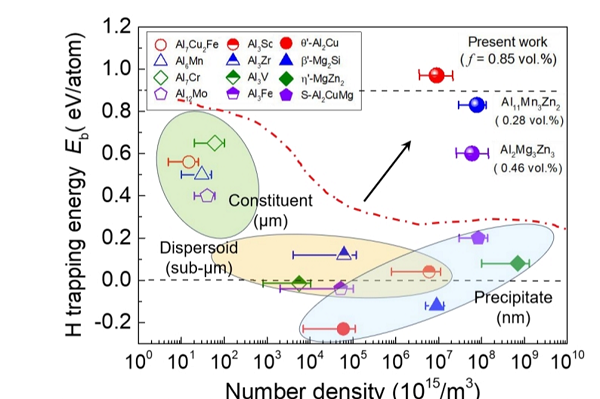

They discovered that the hydrogen-trapping characteristics and distribution features of naturally formed intermetallic compound secondary-phase particles in Al alloys often fail to simultaneously meet the fundamental requirements for high hydrogen absorption.

Micron-sized coarse constituent particles formed during solidification – typically containing low-solubility, high-melting-point elements like Mn, Cr, or Fe – exhibit strong hydrogen absorption capacity due to their high binding energy (Eb), yet their low distribution density and limited interface ratio hinder hydrogen absorption kinetics.

Meanwhile, nano-sized precipitate particles formed during aging, despite their high number density and interfacial area, possess lattice constants nearly identical to the Al matrix, resulting in universally low Eb values that thermodynamically disfavor hydrogen trapping. Submicron dispersoid particles formed during homogenization or solution treatment exhibit hydrogen-trapping properties and distribution characteristics intermediate between constituent and precipitate particles.

Collaborating with domestic and international research teams, the group designed a dual-stage precipitation heat treatment for trace Sc-modified Al-Mg alloys (Mg content: 4.5–7.5 wt.%). In the first stage, dense L12-structured Al3Sc nanoparticles were preformed within grains.

Owing to energy, composition, and concentration fluctuations during solid-state phase transformation, these Al3Sc nanoparticles exhibited a statistically normal size distribution with an average diameter of ~14 nm.

Utilizing the structural similarity between the L12-structured Al3Mg precursor (derived from the Samson-Al3Mg2 phase) and Al3Sc, the second-stage heat treatment induced template-assisted in-situ precipitation of Al3Mg at Al3Sc/matrix interfaces. Atomic-scale interactions between Mg and Sc further facilitated the formation of Samson-structured Al3(Mg,Sc)2 nanophases on Al3Sc particles.

Further studies revealed a strong size dependence in this in-situ phase transformation: Al3Sc nanoparticles smaller than ~10 nm maintained coherent interfaces with the matrix, displaying only limited Mg segregation at boundaries.

Only particles exceeding this critical size developed misfit dislocations at interfaces, promoting Mg diffusion, segregation, and precipitation, ultimately forming core-shell Al3(Mg,Sc)2/Al3Sc composite nanoparticles. Under high-density dual-particle distribution, fine Al3Sc nanoparticles (~2.4 × 10²¹ m⁻³) significantly enhanced alloy strength, while high-Eb Al3(Mg,Sc)2/Al3Sc composite nanoparticles (~5.6 × 10²¹ m⁻³) acted as exceptional hydrogen traps.

Compared to Sc-free alloys, the Al-Mg-Sc system demonstrated a 40-percent increase in strength and a fivefold improvement in hydrogen embrittlement resistance. Even under hydrogen charging up to ~7.0 ppmw, the alloy retained over 90 percent of its tensile elongation, with uniform elongation exceeding 10 percent, outperforming all previously reported Al alloys.

This microstructural design strategy partially resolves the long-standing trade-off between strength and hydrogen embrittlement susceptibility in Al alloys, enabling simultaneous enhancement of both properties.

It provides a novel pathway for developing next-generation high-strength, hydrogen-tolerant Al alloys. Building on decades of fundamental research into complex metallic phases, hydrogen-resistant Al alloys may serve as a breakthrough, unlocking broader structural-functional integration prospects in magnetic, electrical, transport, and superconducting applications.

The findings, titled Structurally complex phase engineering enables hydrogen-tolerant Al alloys, were published online in Nature.